Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Modèle: Airbag System

marque: HTD

Lieu d'origine: CHINE

Positionnement du produit :

L'anneau de retenue du gonfleur HTD est le composant porteur essentiel du système d'airbag automobile, conçu pour ancrer de manière sûre et précise le gonfleur à la structure de la carrosserie du véhicule. Agissant comme le « squelette structurel » du module d'airbag, il doit résister et transférer instantanément l'énorme force de réaction provenant de l'allumage du gonfleur et des charges d'impact au châssis du véhicule lors d'une collision, tout en assurant la stabilité de position absolue du gonfleur. Fabriqué à partir d'alliages d'acier/aluminium à haute résistance à l'aide de processus d'estampage/moulage sous pression de précision, il réalise l'intégration parfaite d'une résistance ultra-élevée, d'une excellente résistance à la fatigue, d'un positionnement précis et d'un anti-desserrage fiable sous des charges dynamiques extrêmes, servant de base mécanique pour le déploiement rapide et précis du système d'airbag.

Paramètres de performance clés de l'estampage :

| Category | Specific Parameters | Test Standard |

| Primary Material | High-Strength Steel (B340LA, HC420/DP600), High-Strength Aluminum Alloy (AlSi10Mg), Custom | Customer Specified / With Material Certificate |

| Static Strength | Tensile Strength ≥ 400 MPa (Steel), ≥ 250 MPa (Al); Yield Strength meets design target | ISO 6892-1 / ASTM E8 |

| Dynamic Performance | Crash Impact Energy Absorption ≥ Specified value; Fatigue Life ≥ 1×10⁶ cycles (load spectrum) | Enterprise Standard / Customer DV Specification |

| Mounting Accuracy | Inflator Mounting Hole Position Tolerance ≤ ±0.2mm; Mounting Surface Flatness ≤ 0.3mm | 3D Dimensional Report / CMM Inspection |

| Torque Performance | Fastener point Torque-Angle Curve compliant; Anti-loosening design, post-vibration torque decay < 15% | ISO 16047 / VW 01103 |

| Corrosion Resistance | Steel: Zinc-Aluminum Coating/Dacromet (≥720h NSS); Aluminum: Anodizing/Micro-arc Oxidation | ISO 9227 Salt Spray Test |

| Process Characteristics | Precision Stamping (Steel) / High-Pressure Die Casting (Al), burr-free in critical areas | VDA 19.1 Cleanliness Control |

| Step | Core Process | Key Technical Points | Output Standard |

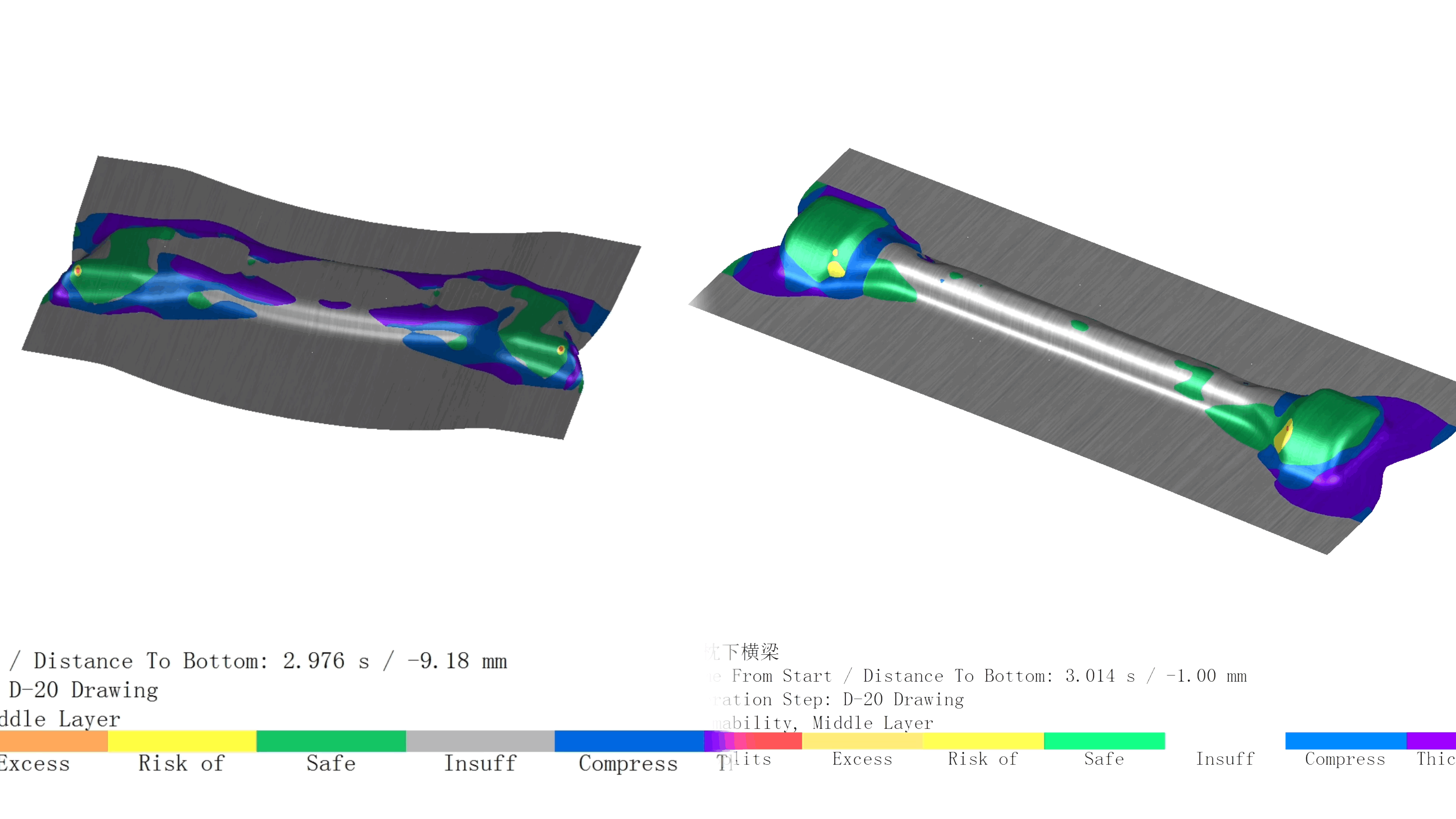

| 1 | Simulation-Driven Design | Multi-disciplinary simulation optimization (Crash, Vibration, Fatigue) | Simulation report approved, safety factor meets target |

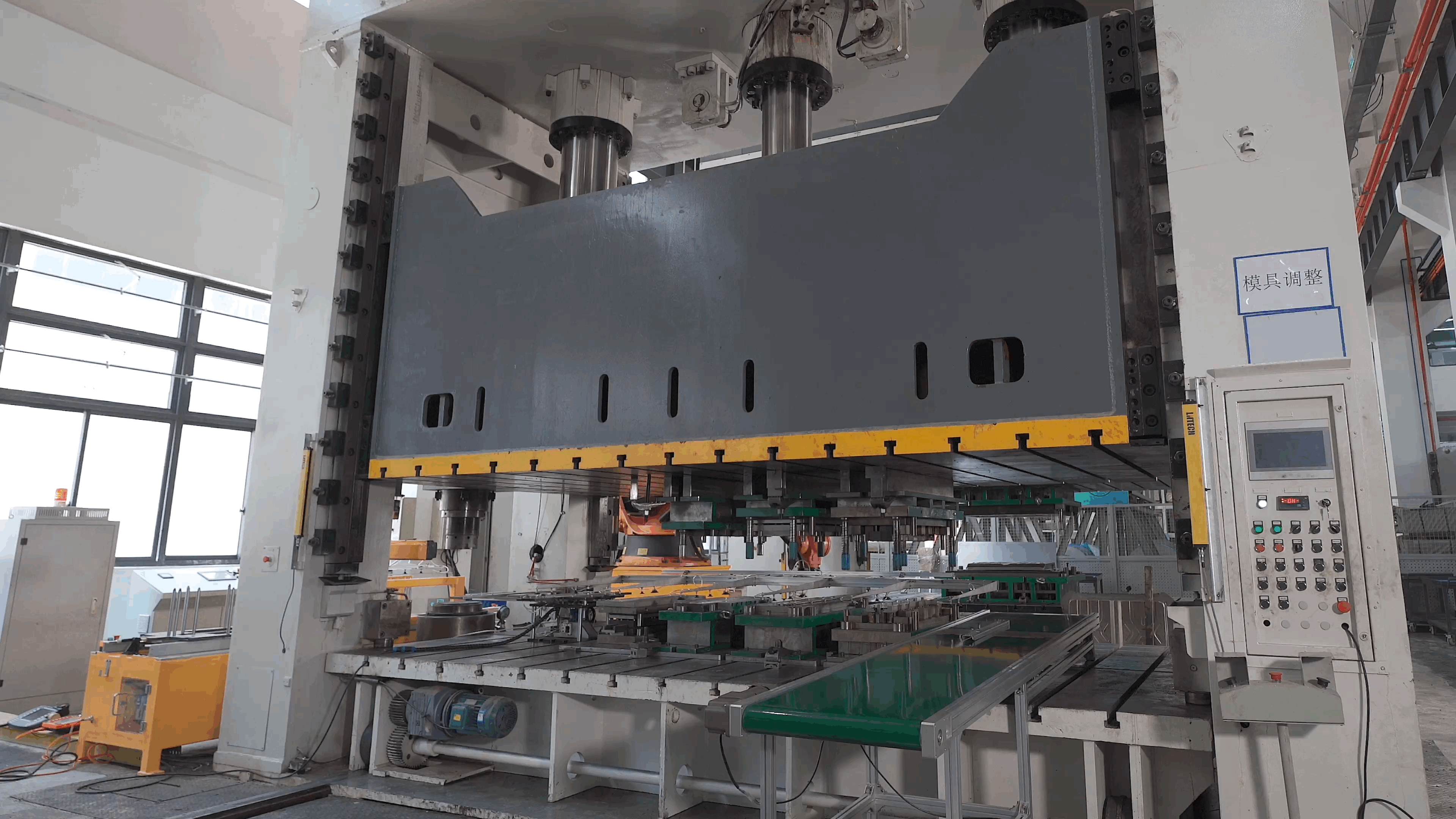

| 2 | Precision Forming | Hot Stamping / High-Vacuum Die Casting, real-time in-mold temperature & pressure monitoring | Material strength and microstructure qualified, free of forming defects |

| 3 | Performance Heat Treatment | Controlled atmosphere continuous furnace heat treatment, closed-loop process control | Mechanical properties (Tensile, Yield, Elongation) 100% meet spec |

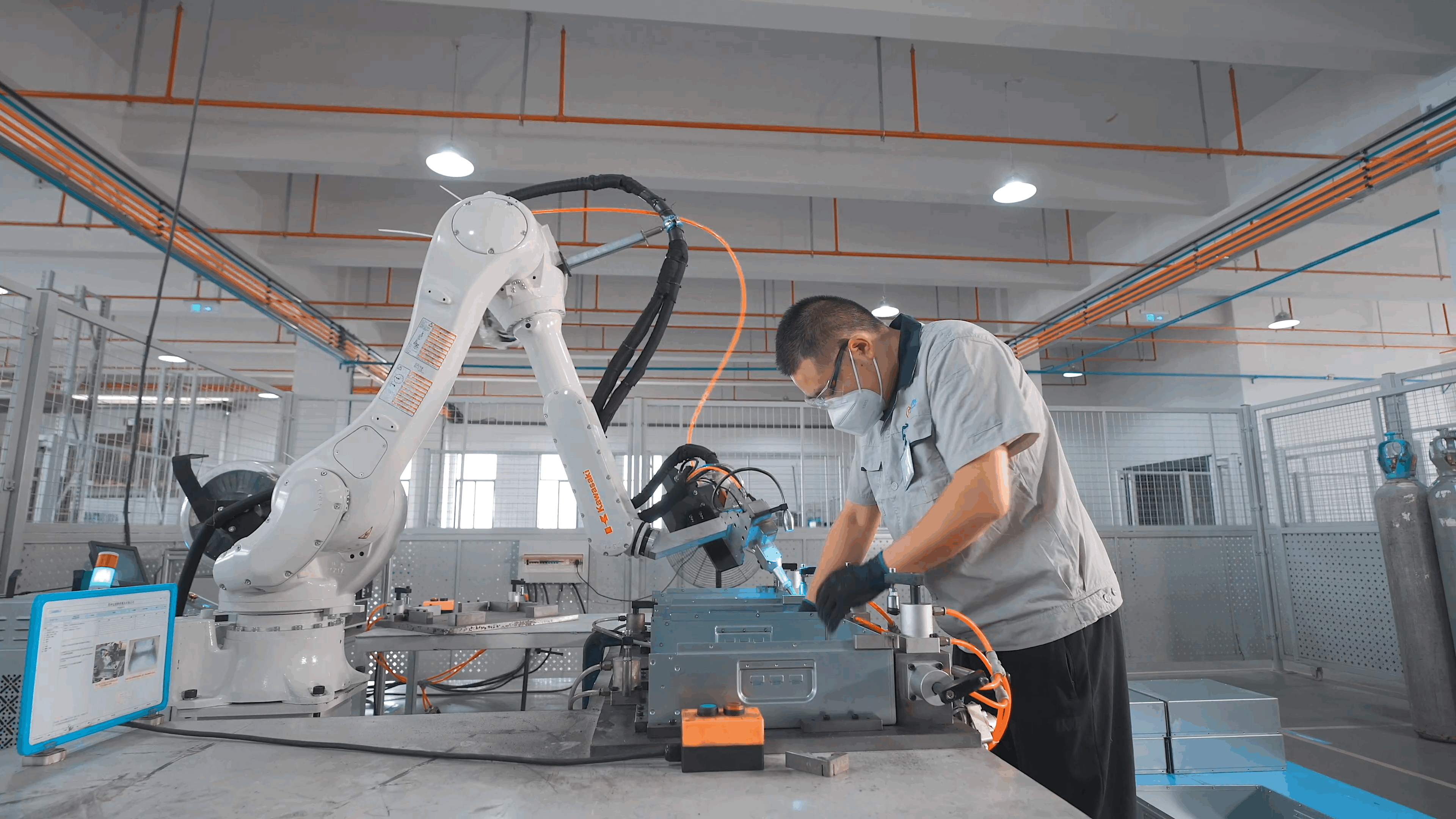

| 4 | Intelligent Finishing | Robot adaptive machining, in-line laser measurement & compensation | Key dimension CPK≥1.67, position tolerance 100% passed |

| 5 | Surface Treatment & Assembly | Eco-friendly coating, clean assembly, 100% optical & torque inspection | Salt spray, coating thickness, assembly torque 100% passed |

The file is encrypted. Please fill in the following information to continue accessing it

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.