Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Modèle: Electric Control System

marque: HTD

Lieu d'origine: CHINE

Positionnement du produit :

La barre omnibus de l'unité de distribution haute tension HTD est le composant conducteur central intégré à l'intérieur de l'unité de distribution d'énergie (PDU/BDU) responsable de la distribution, de la conversion et de la protection de l'énergie électrique. Agissant comme « squelette » et « vaisseaux sanguins » du système de distribution d’énergie, il collecte le courant élevé à partir du circuit principal et, grâce à sa conception multibranches intégrée, distribue l’énergie de manière précise et fiable aux différents sous-circuits. Utilisant des alliages de cuivre/aluminium hautement conducteurs et une technologie de moulage par insert, il atteint l'équilibre parfait entre faible impédance, capacité de transport de courant élevée, sortie multicanal et indice d'isolation élevé dans un espace limité, ce qui en fait un élément clé pour améliorer la densité de puissance, la sécurité et la fiabilité globales du système.

Paramètres de performance clés du moulage par insertion :

| Category | Specific Parameters | Test Standard |

| Conductive Material | T2 copper (nickel/tin plated), High-purity aluminum (AL1000 series), Copper-aluminum composite | ASTM B209 / GB/T 5585.1 |

| Rated Voltage | Max. working voltage: DC 1500V / AC 1000V | IEC 60947 |

| Current-Carrying Capacity | Continuous current 250A – 5000A (section-optimized), Peak current ≥ 1.5x rated value, Temp. rise ≤ 40K (@25℃) | Enterprise standard / Thermal simulation |

| Insulation Performance | Withstand voltage ≥ 3000V AC (50Hz), Protection class IP67, Comparative Tracking Index CTI ≥ 600V | ISO 20653 / UL 746 |

| Structural Design | Integrated multi-branch topology, with mounting base and anti-loosening features, supports bolted/laser welding | Real-cabinet vibration test (IEC 60068-2-6) |

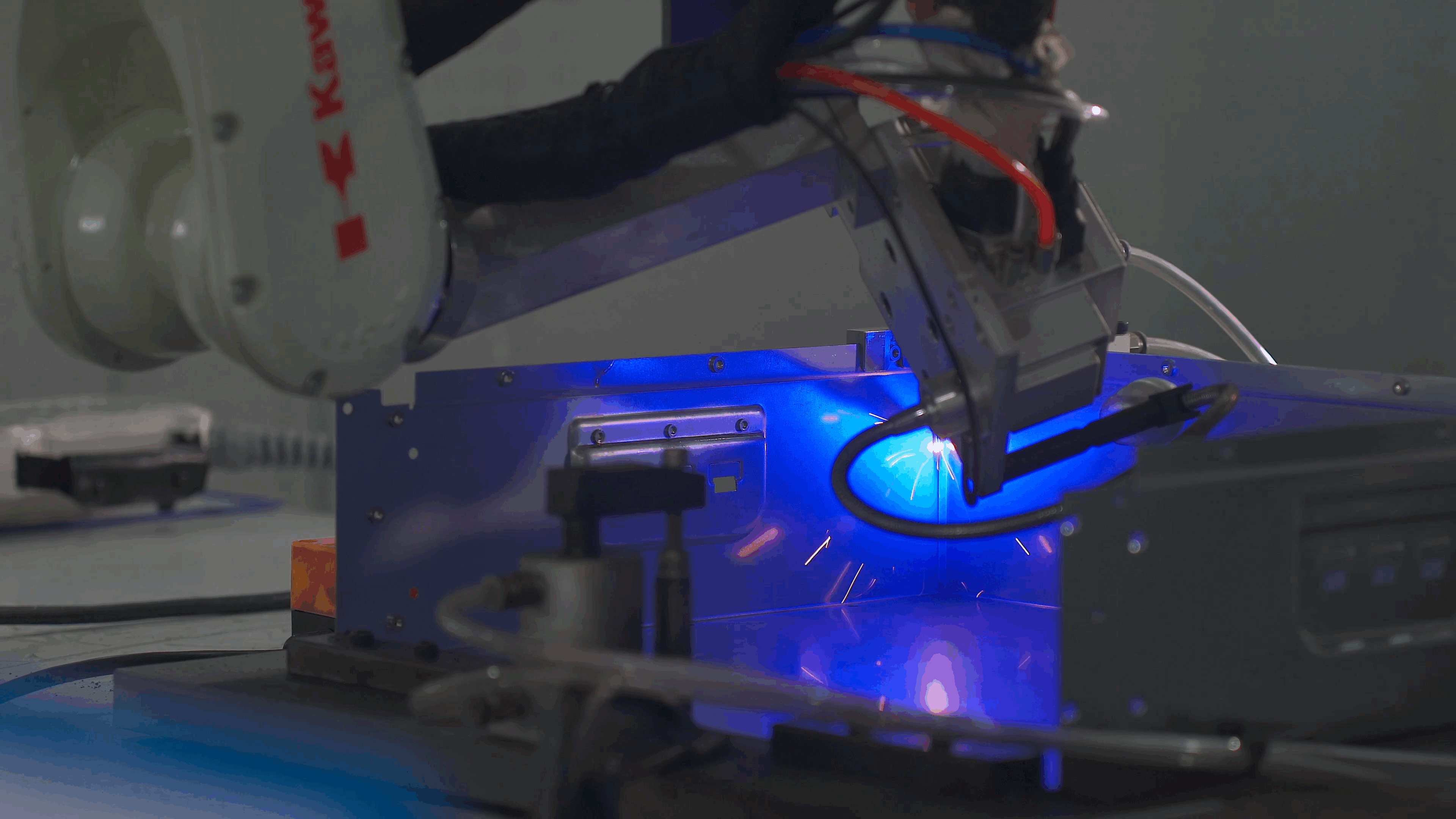

| Connection Method | Bolted connection (torque accuracy ±0.5N·m, sizes M6-M16), Optional laser welding (penetration ≥0.5mm) | IEC 60947 |

| Lightweight Benefit |

Aluminum solution weight reduction ≥30% vs. equivalent copper, Cu-Al composite reduction ≥35%

|

Real-cabinet comparison |

| Step | Core Process | Key Technical Points | Output Standard |

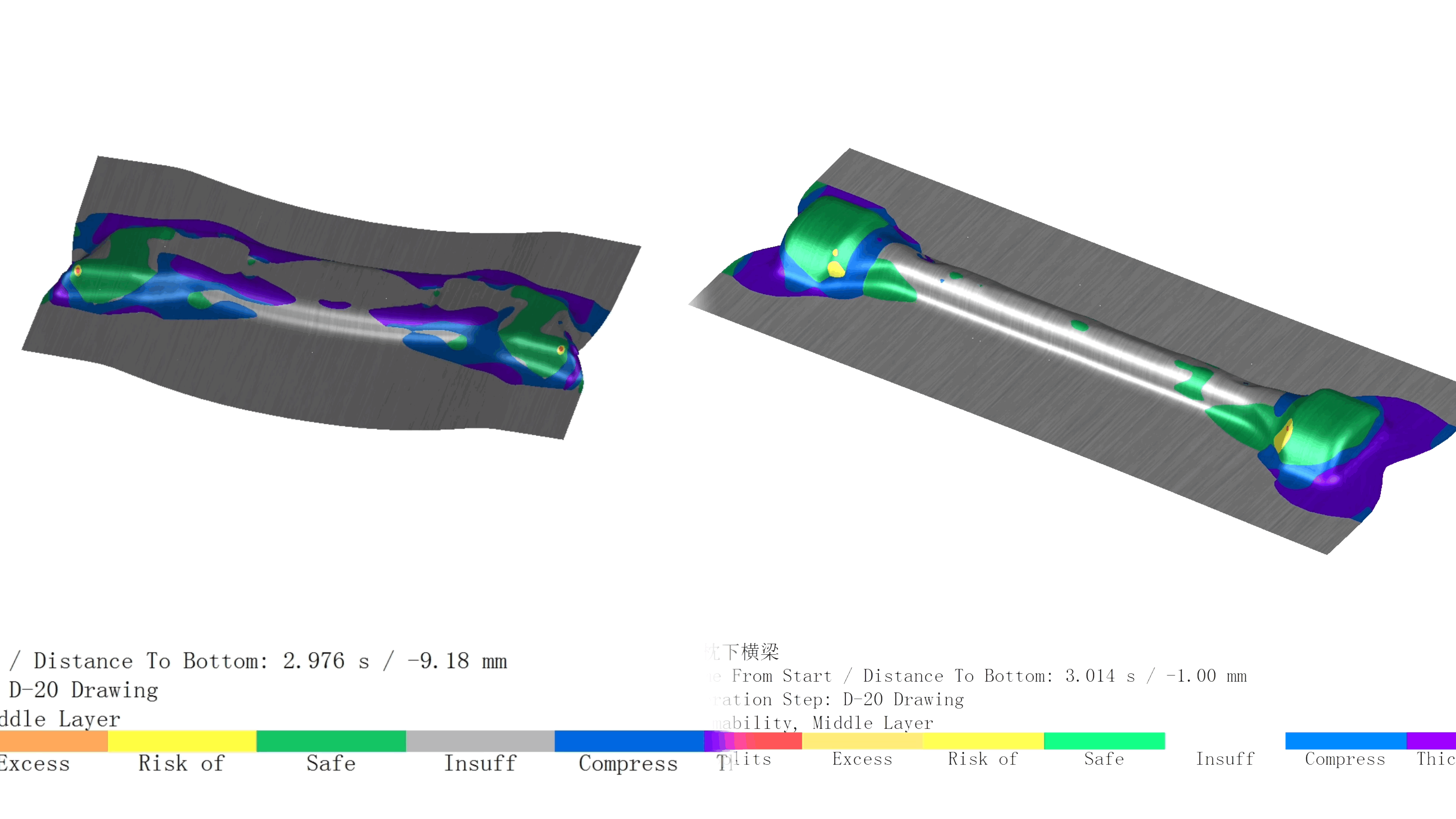

| 1 | 3D Design & Simulation | Electrical topology & thermal simulation, Mold CAE flow analysis | Current, temp. rise, insulation meet design specs |

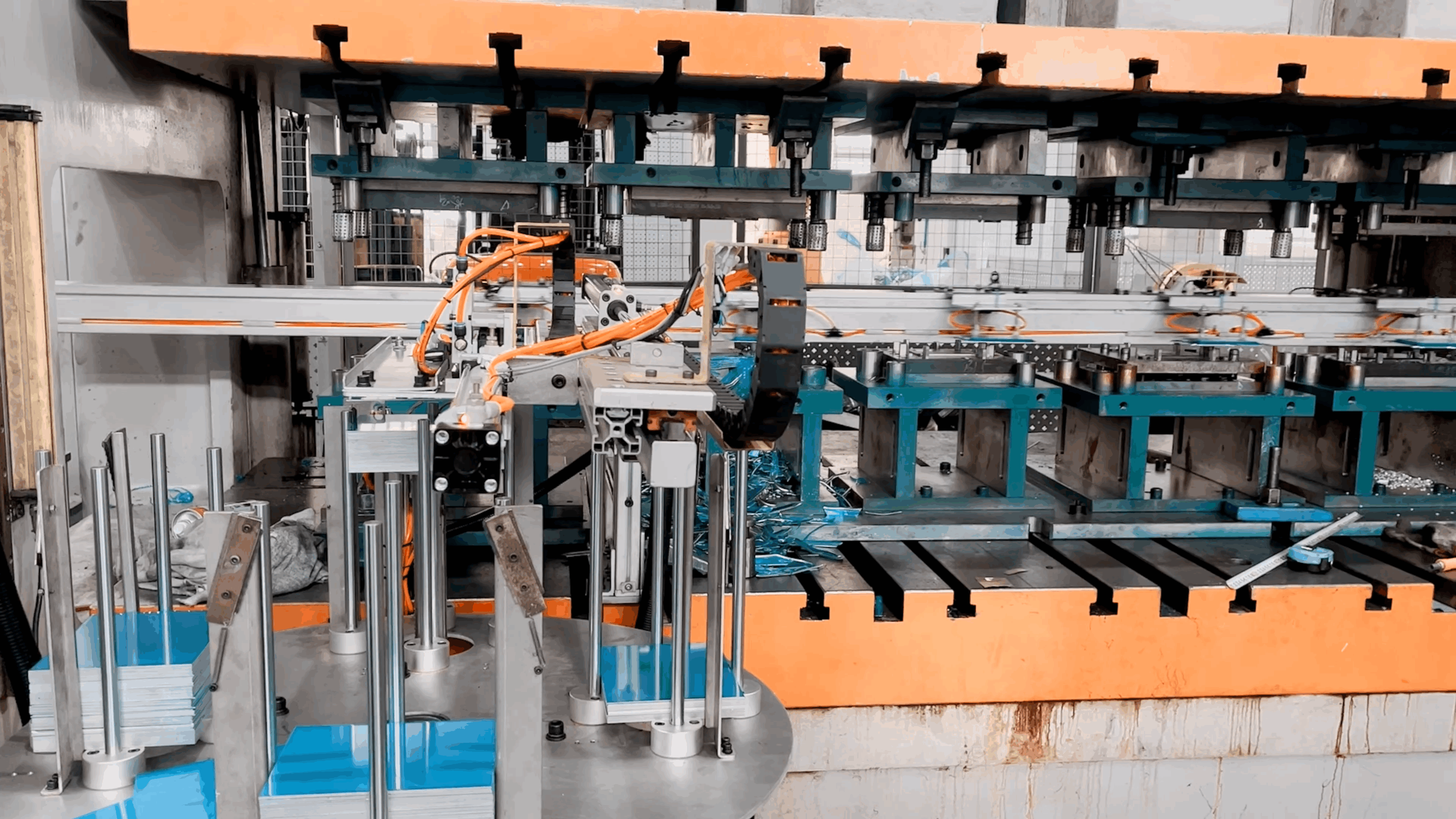

| 2 | Precision Stamping & Bending | Multi-station progressive die, Variable cross-section, Precision bending | Dimensional tolerance ±0.1mm, Burr/crack free |

| 3 | Connection & Pre-assembly | Laser welding/Bolt pre-tightening, Insert nut pressing | Connection resistance deviation ≤3%, False weld rate<0.1% |

| 4 | Insert Molding | PPS/PA material, Precise mold temp. control, Retractable supports | Insulation layer free of voids/sink marks, Withstand voltage ≥3000V AC |

| 5 | Full Performance Test | Loop resistance, Partial discharge, Temp. rise cycle, Salt spray test | Defect rate ≤0.1%, Full MES data traceability |

The file is encrypted. Please fill in the following information to continue accessing it

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.