Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Modèle: Battery System

marque: HTD

Lieu d'origine: CHINE

Positionnement du produit :

La barre omnibus interne du bloc de batterie HTD est le composant conducteur principal responsable de la collecte et de la distribution du courant entre les cellules de la batterie au sein d'un module. Utilisant des matériaux composites en aluminium recouvert de cuivre ou du cuivre/aluminium de haute pureté, il atteint un équilibre optimal entre faible résistance, capacité de transport de courant élevée et conception légère grâce à des processus d'estampage, de pliage et d'isolation de précision, garantissant une transmission de courant stable et sûre au sein de la batterie.

Paramètres de performance clés du moulage par insertion :

| Category | Specific Parameters | Test Standard |

| Material Options | Copper-clad aluminum composite (Cu layer 30%-40%), T2 copper, AL1000 series high-purity aluminum | ASTM B209 / GB/T 3190 |

| Conductivity | Copper-clad aluminum resistivity ≤0.026 Ω·mm²/m; Pure copper resistivity ≤0.0178 Ω·mm²/m | GB/T 5585.1 |

| Current-Carrying Capacity | Continuous current 200-600A (section-dependent), temperature rise ≤40K (@25°C ambient) | Enterprise standards / Thermal simulation validation |

| Structural Design | Integrated anti-expansion ribs/buffer slots, pre-compensating for cell cycling expansion stress | Real-pack cycle testing |

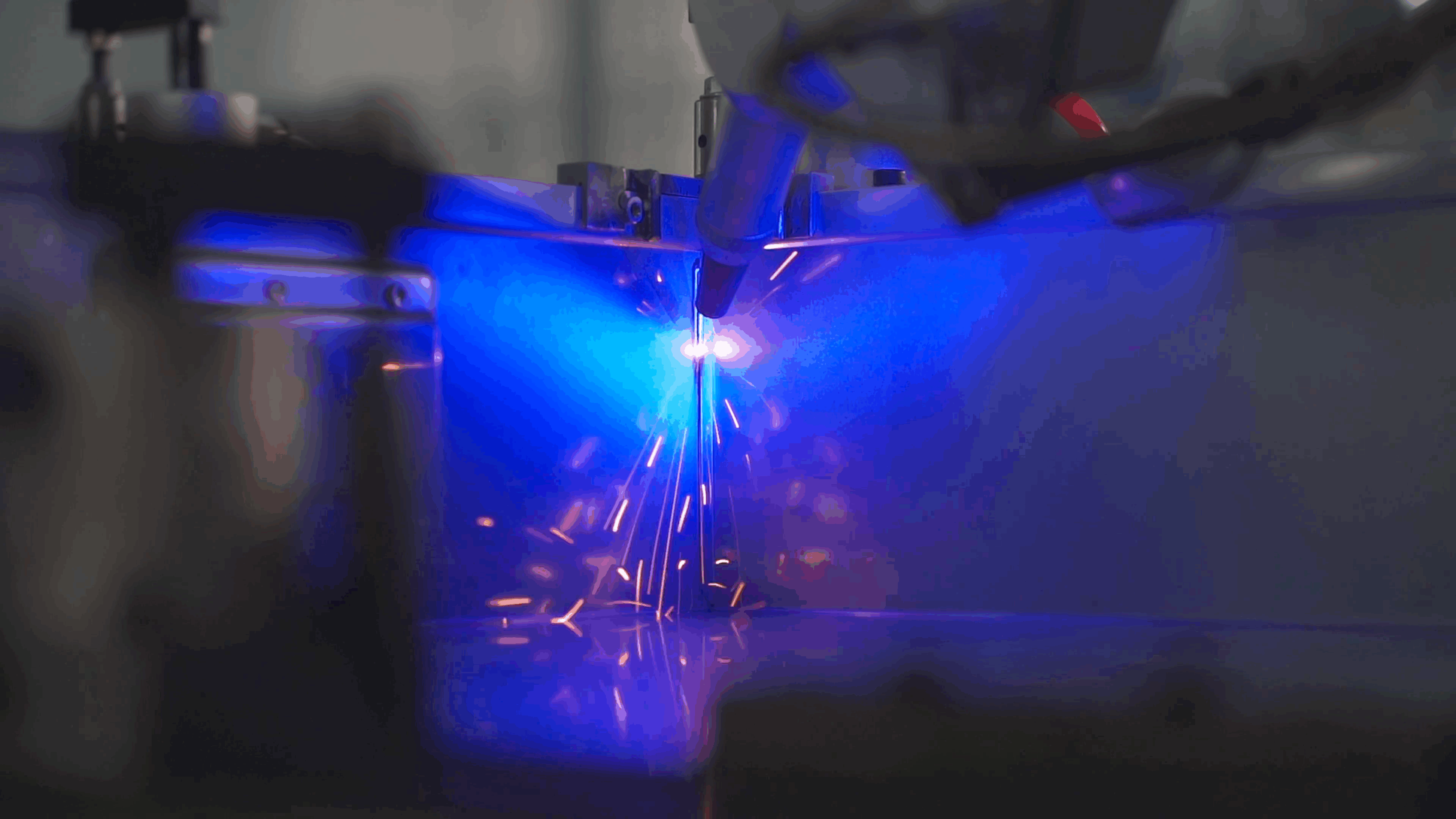

| Connection Process | Laser welding (depth ≥0.5mm) or bolted connection (torque accuracy ±0.5N·m) | IEC 60947 |

| Insulation Treatment | Optional insert molding (PA, PPS), spraying or sleeving, withstand voltage ≥2500V AC | ISO 20653 |

| Lightweight Benefit |

Copper-clad aluminum solution reduces weight by >35% compared to pure copper; Aluminum solution reduces weight by 50% |

Real-vehicle comparison validation |

| Step | Core Process | Key Technical Points | Output Standard |

| 1 | Material Composite Casting | Core-filled continuous composite casting; precise temperature control (shell casting 1000-1100°C, aluminum filling 740-760°C) | Cu/Al cross-section ratio 2:7~2:5; interface bond strength ≥100MPa |

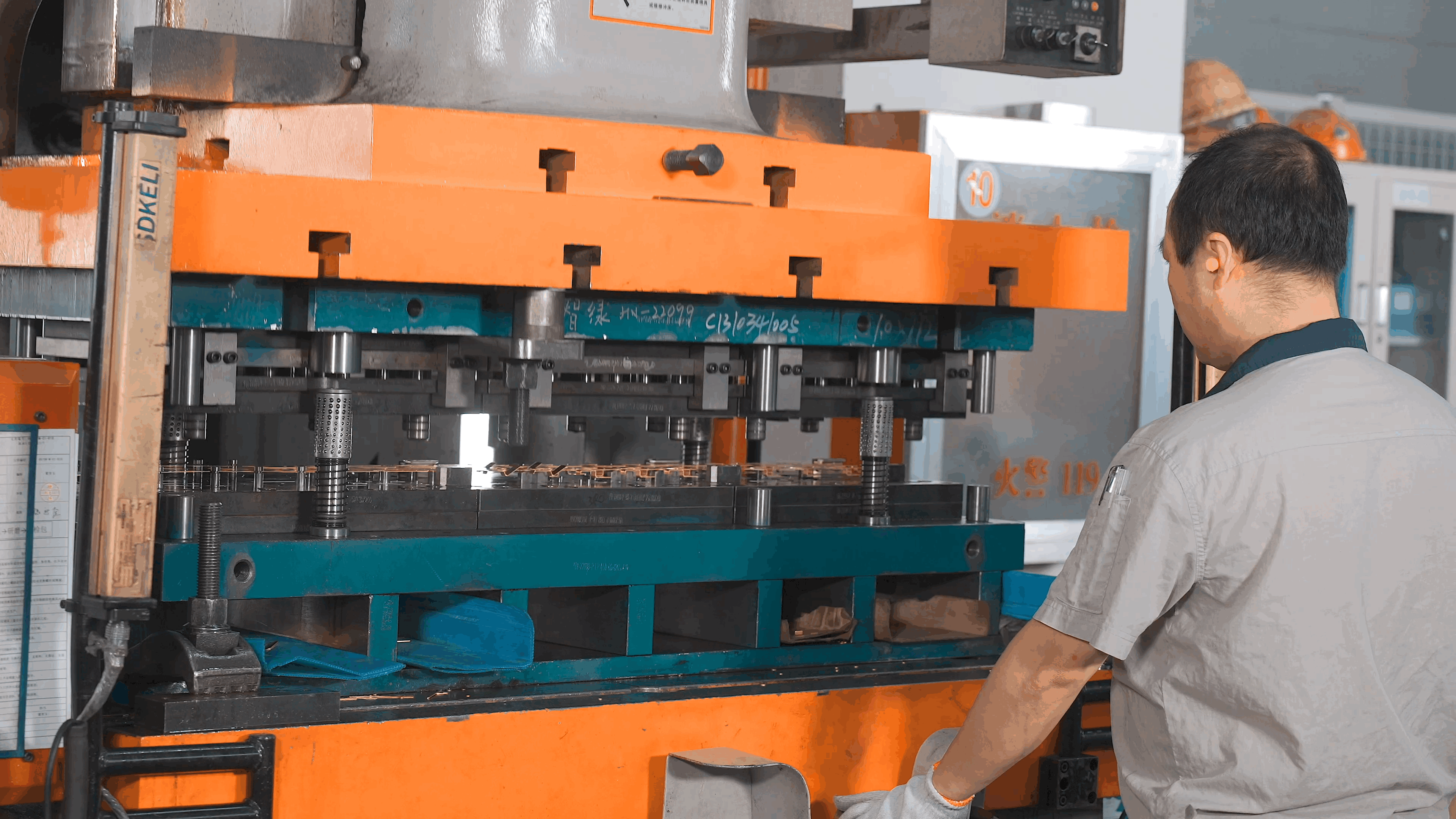

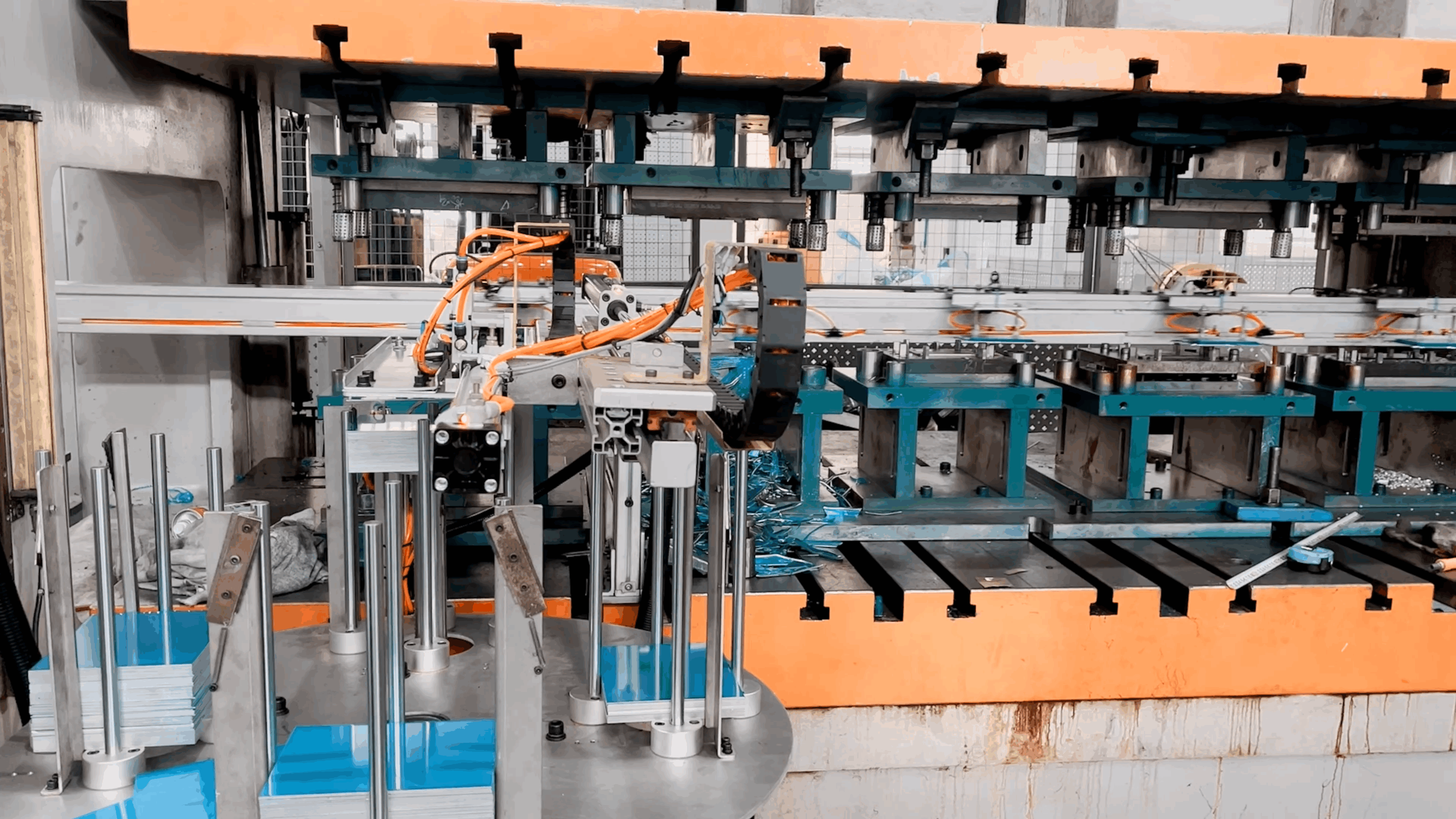

| 2 | Precision Stamping & Bending | Multi-directional CNC bending equipment one-time forming; integrated anti-expansion rib design | Dimensional tolerance ±0.1mm; structure free from cracking or wrinkling |

| 3 | Welding Integration | Laser welding depth ≥0.5mm; false welding rate <0.1% | Stable resistance meeting standards; reliable connection points |

| 4 | Insulation Treatment | PE heat-shrink tubing hot air shrinkage or epoxy powder dip coating; withstand voltage ≥2500V | Insulation layer uniform without defects; IP67 protection level |

| 5 | Inspection & Packaging | Full-size inspection + electrical performance test; MES system traceability | Defect rate ≤0.1%; supports full lifecycle quality traceability |

The file is encrypted. Please fill in the following information to continue accessing it

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.